Airless pump bottles have become increasingly popular in the cosmetics and skincare industry, as they offer a superior alternative to traditional packaging. But how do these innovative containers work, and what makes them so beneficial? In this article, we’ll explore the inner workings of airless pump bottles, their benefits, and how they’re changing the way we store and use our favorite products.

What Are Airless Pump Bottles?

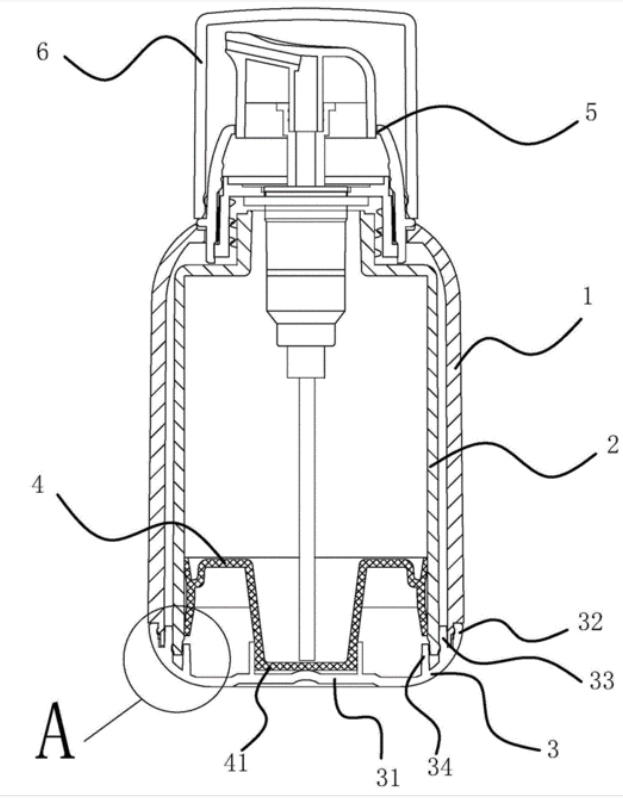

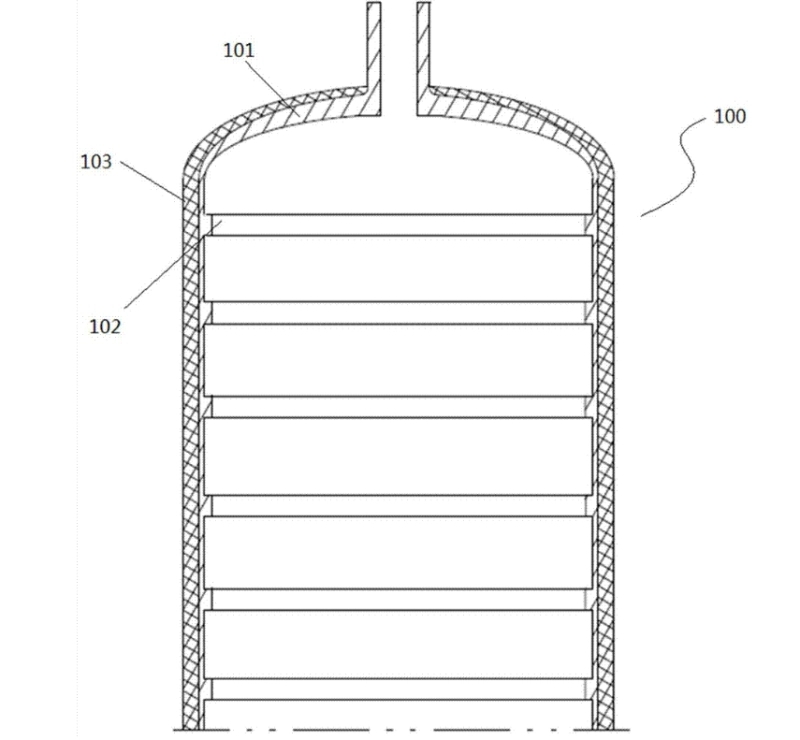

Airless pump bottles are packaging that utilizes vacuum technology to dispense the contents without letting air enter the container. These bottles are made of either plastic or metal and contain three main parts: the outer container, the inner chamber, and the pump mechanism. These components form a closed system that ensures the contents stay fresh, potent, and contamination-free.

How Do Airless Pump Bottles Work?

Vacuum Technology

The secret behind the effectiveness of airless pump bottles lies in their vacuum technology. When you press the pump, the pressure forces the product out of the container through a small opening, also known as a nozzle. Simultaneously, the vacuum system pulls the inner chamber upwards, ensuring no air enters the bottle.

Inner Chamber

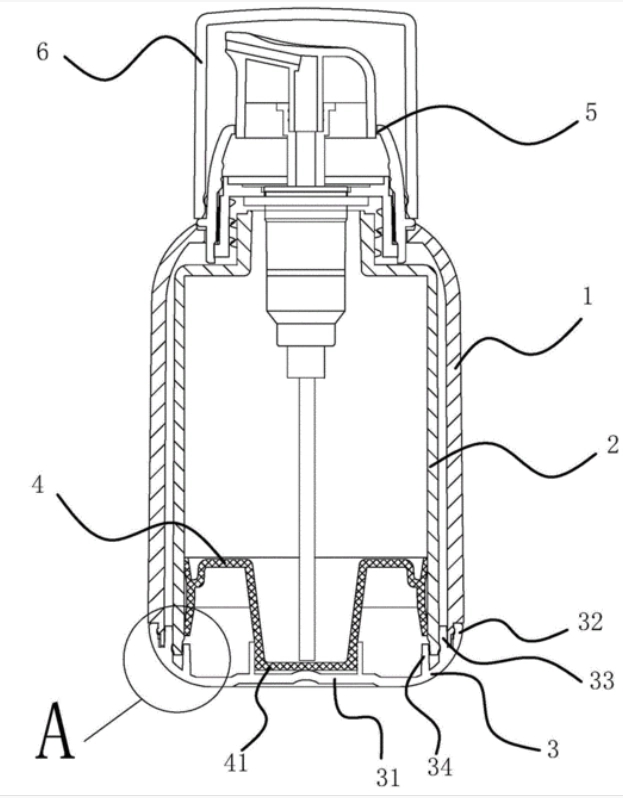

The inner chamber plays a critical role in the airless packaging process. When dispensing the product, the room moves up, filling the void left by the distributed product. This movement creates a vacuum seal, preventing air from entering the container and maintaining the integrity of the remaining contents.

Pump Mechanism

Airless pump bottles feature a unique pump mechanism that differs from traditional pumps. While conventional pumps rely on a dip tube to draw the product out, airless pumps use a plate at the bottom of the inner chamber. This plate moves upward as the product is dispensed, ensuring no air enters the bottle, and the product stays fresh.

Benefits Of Airless Pump Bottles

Safety issues often accompany Product Preservation

Chemical Preservatives

One of the most significant advantages of airless pump bottles is their ability to preserve the potency and freshness of the contents. By preventing air from entering the container, they protect the product from oxidation and spoilage, extending its shelf life.

Hygiene

Airless packaging eliminates the need for dipping fingers or applicators into the product, minimizing the risk of contamination. This feature is precious for skincare and cosmetic products, as it helps maintain the product’s cleanliness and effectiveness.

Reduced Waste

Traditional containers often leave residual products that are difficult to access, leading to waste. Airless pump bottles, however, dispense nearly every last drop of the product, ensuring you get the most out of your purchase.

Precise Vacuum Dispensing

The pump mechanism in airless bottles allows for precise and controlled dispensing. This feature helps prevent product waste and ensures that you apply the correct amount of product every time.

Airless pump bottles have revolutionized cosmetic and skincare packaging, offering numerous benefits such as product preservation, improved hygiene, reduced waste, and precise dispensing.

By understanding how these innovative containers work, you can make informed decisions when selecting the best packaging for your skincare and cosmetic needs.

So, the next time you’re shopping for new products, consider opting for those housed in airless pump bottles – your skin and wallet will thank you!

Afshan offers expert wholesale, production, design, and customization services for airless pump bottles. You can explore Afshan’s premium airless pump bottle selection or contact our experienced team for your information.